Sendust ferrite core

It’s mainly used to replace iron powder core as its core loss is 80% less than the powdered iron, so it can be applied with the frequency above 8kHz. Sendust core has a saturation flux density of 1.05T and permeability from 14 to 125. Sendust core also has better DC bias characteristics than MPP and the best cost performance. It is mainly applied in AC inductor, output inductor, in-line filter, power factor correction inductor etc. It can also be used as transformer core in some circumstances.

Material composition: 85% iron, 6% aluminum, 9% silicon; magnetic permeability from 26 to 125;

Mainly used in switching power supplies such as power inductors, AC inductors, output inductors, line filters, power factor correction circuits, etc., and sometimes replace air gap ferrites as transformer cores;

Main features and advantages: When reducing the effective permeability of the magnetic core, the small air gap evenly distributed in the magnetic core can make the winding bear a large direct current component without saturating the magnetic core during the application of DC pulse; In the frequency range, it has lower magnetic core loss than the existing iron powder core materials. It has a similar effect at any Gaussian value. Under the same test conditions, the temperature rise of the sendust core is always less than half of the iron powder core, and the core loss is only 1/2 to 1/ of the iron powder composition. 4. Under high frequency conditions, they are superior to iron powder cores and can meet the needs of high-frequency power conversion equipment for extremely high-efficiency inductors; they can be used at frequencies above 8KHz; saturation magnetic induction is around 1.05T; magnetic The strain coefficient is close to zero, and no noise is generated when working at different frequencies; it has a higher DC bias capability than MPP; it has the best cost performance.

The Curie temperature of the sendust core is 500°C, and the core coating can ensure continuous use at 200°C;

The black polyester paint coating of the magnetic core can ensure that the coating to the magnetic core can withstand the voltage of 500V or the voltage of 1KV between the windings.

Size and dimensions:

Core Dimensions:

|

|

ODImax) |

ID(min) |

HT(max) I |

|

|

Before coating |

(mm) (inch) |

57.15 2.250 |

26.39 1.039 |

15.24 0.600 |

|

After coating |

(mm) |

58 00 |

26.60 |

16.10 |

|

By) |

(inch) |

2.285 |

1.007 |

0635 |

Magnetic Dimensions:

|

Cross Section (Ae) |

Path Length (Le) |

Window Area (Wa) |

Volume (Ve) |

|

2.29cm2 |

12.5cm |

5.14cm2 |

28.6cm2 |

|

0.355in2 |

4 93in |

1,014,049cmil |

1.75in3 |

Electrical properties:

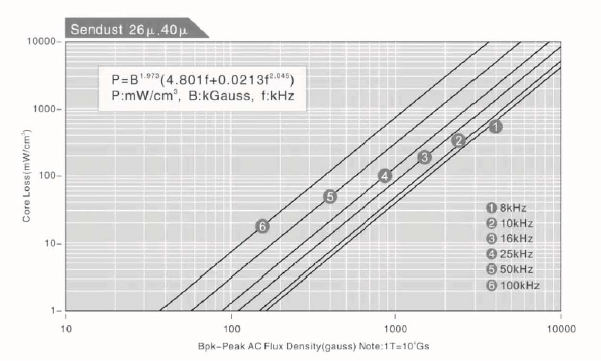

Core loss, 26u, 40u

Core loss, 60u, 75u, 90u, 125u

Application:

Smart choice for PFC inductor;

Switching regulator inductors, In-line noise filters;

Pulse transformers and flyback transformers;