-

PFC inductor

PFC inductor, also called toroidal inductor, Capable of handling very high DC bias current with minimal inductance roll off.

“Power Factor Correction” The power factor is the ratio of the effective power divided by the total power consumption (apparent power).

-

High flux custom toroidal power inductor

The toroidal coil inductance is a very ideal shape in inductance theory. It has a closed magnetic circuit and few EMI problems. It makes full use of the magnetic circuit and is easy to calculate. It has almost theoretical advantages. It is all-inclusive toroidal coil inductance. However, there is one biggest disadvantage. , It’s not easy to scratch the thread, and the process is mostly handled manually.

-

High Current Wirewound Customize Good Quality Factory Product

Core Material: Iron Power Core

With Helical Wound Surface Mount inductor, It is Capable of handling very high DC bias current with low inductance roll off.

Induction/Size/Wire diameter/Electric Current :Normally our customer specify the specs (size, inductance, current) and we built to meet the specs.

-

SMD common mode inductor

We could provide different type and size of SMD common mode inductors. In situations where noise occurs around a signal, Ming Da’s broad range of common mode chokes suppresses interference cleanly and efficiently without compromising signal integrity. Used in moderate to severe conditions like telecommunications systems, industrial equipment and automotive power supply, our extensive portfolio of products is designed to filter noise and optimize application performance and power supply. Our unique materials withstand high temperature and power situations and will keep your systems running consistently and at top speed.

-

Common mode power line choke uu 10.5

With below information, we could help to customized the product:

1. Current and inductance request

2. Working frequency and size request

UU10.5, UU9.8, UU16 is available for your choice.

-

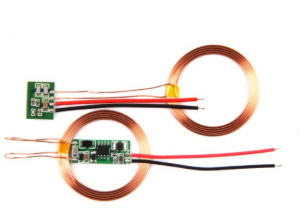

Wireless charging module

Our wireless charging module include wireless transmitter coil and wireless receiving coil, could customize the coil module according to customer’s request.

-

SMD air coil

The main characteristic is extremely high Q factors and very tight inductance tolerance, As their name implies, air-core inductors do not use a magnetic core, resulting in the high Q and the lowest possible losses for high-frequency applications.

-

Antenna air coil

Air-core coils can usually be used as current transformers, with a wide frequency band, small size, light weight, convenient for digital measurement, and microcomputer protection. It is widely used in television technology, audio technology, communication transmission, reception and power filtering, VCD radio head, antenna amplifier, radio cassette recorder, antenna microphone and other fields.

-

Inductor air coil

With more than 100 automatic winding machines in our factory, We could ensure about the quick lead time and product quality.

Just provide us the basic size, wire diameter and turns request, we could wind anything suitable for you.

-

Self adhesive air coil

Self adhesive copper air coil is widely used in medical instrument, outdoor sports equipment.

Just need to provide the basic information from your engineer, we could help to design and customize the product just for you.

-

Wireless power transfer receiver coil

Advantage of this high quality coil with litz wire and ferrite fortification in the center is that devices using this solution can be charged on charging stations of both standards.

This wireless receiver coil is very ideal for smartphone charging, hand-held devices

Customized products could be provided according to the different request.

-

Wireless charging coil

According to the needs of the circuit, select the winding method:

When winding the wireless charging coil, it is necessary to determine the winding method according to the requirements of the wireless charging device circuit, the size of the coil inductance and the size of the coil, and then make a good mold. Wireless charging coils are basically wound from the inside to the outside, so first determine the size of the inner diameter. Then determine the number of layers, height, and outer diameter of the coil according to factors such as inductance and resistance.