OEM/ODM Factory Air Heater Coil - Air core inductor coil – Mingda

OEM/ODM Factory Air Heater Coil - Air core inductor coil – Mingda Detail:

With more than 15 years experience in manufacturing the coil, we could manufacture the suitable coils for you according to your request.

The earliest enameled wire for hollow coils is oily enameled wire, which is made of tung oil. The paint film has poor abrasion resistance and cannot be directly used to make motor coils and windings. It needs to be covered with cotton yarn during use. Later, polyvinyl formal enameled wire came out, and its mechanical properties were greatly improved. It can be directly used in motor windings and is called high-strength enameled wire.

With the development of weak current technology, there has been a self-adhesive enameled wire, which can obtain a coil with better integrity without dipping and baking. But its mechanical strength is poor, and it can only be used in micro motors and small motors. In addition, in order to avoid the trouble of first removing the paint film during soldering, direct solder enameled wire has been developed. The paint film can fall off in the high-temperature tin enamel tank to make the copper wire easy to solder. Due to the increasing application of enameled wires and stricter requirements, composite enameled wires have also been developed. The inner and outer paint films are composed of different polymer materials, such as polyesterimide/polyamideimide enameled wire.

Advantages:

1.Customized according to your unique request

2. Using Elektrisola wire, high stability.

3. Precision wound coil and 100% all tested to ensure the quality.

4. Build to confirm ROHS compliant

5.Short lead time and quick sample

6.Samples could be provided for your testing

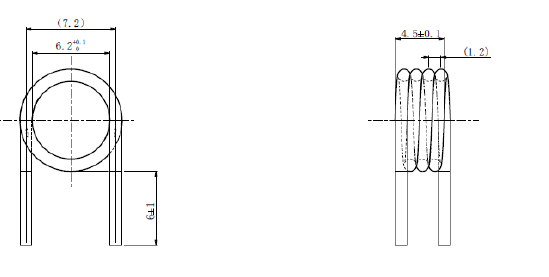

Size and dimensions:

Application:

1. Satellite communication systems, test equipment

2. Microwave equipment, Band pass filters

3.Television circuits.

4.AM/FM radio transmitters /receivers.

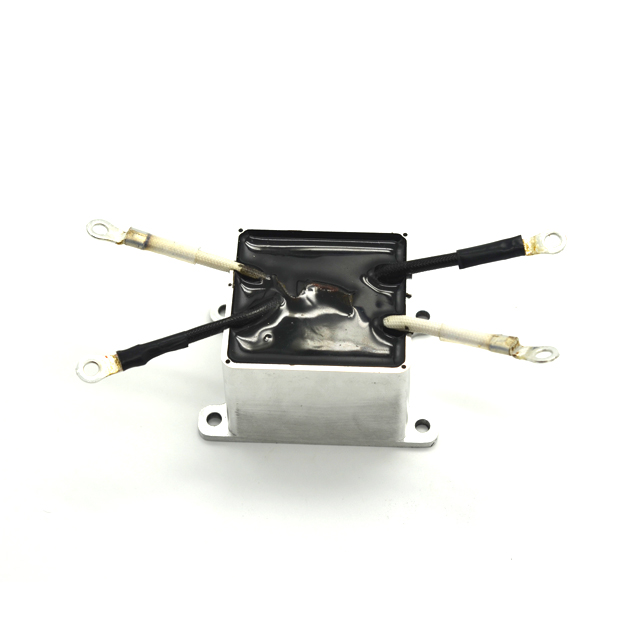

Product detail pictures:

Related Product Guide:

What’s the role common mode choke play in daily?

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for OEM/ODM Factory Air Heater Coil - Air core inductor coil – Mingda , The product will supply to all over the world, such as: Pakistan, Singapore, Norway, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.