Massive Selection for Common-Mode Inductor - SMT power inductor – Mingda

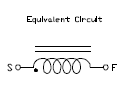

Massive Selection for Common-Mode Inductor - SMT power inductor – Mingda Detail:

Advantages:

1. Carrier tape packaging use for SMT

2. High rated current, Low DCR.

3. Suitable for reflow SMT Craft soldering.

4. Build to RoHS compliance and lead free

5. High saturation core material and small size

6. Saturation currents up to 14 A

7.CD31/CD32/CD42/CD43/CD52/CD53/CD54/CD73/CD75/CD105/CD105 is available for your choice.

8. Package: Tape&Reel packaging.

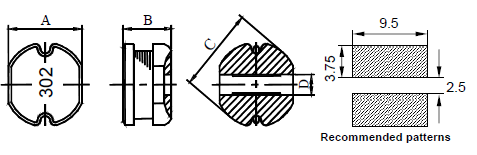

Size and dimensions:

|

A |

B |

C |

D |

|

9.0±0.3 |

6.4±0.3 |

Φ10.0±0.3 |

3.0±0.3 |

Electrical properties:

|

ITEM |

SPEC. |

TOLERANCE |

TESI FREQUENCY |

TEST EQUIPMENT |

|

INDUCTANCE |

3.0mH |

±10% |

100kHz/0.25V |

HP-4284A |

|

DCR |

7.2Ω |

Max. |

at25°C |

CH-502A |

|

IDC |

0.32A |

L0A*90% Mim. |

10kHz/0.25V |

CD106S+CD1320 |

Applications:

1. Switching regulators with low operating voltages (graphic cards, embedded PC-Cards, mainboards)

2.Integrated DC/DC converter

3.Lighting LED , Portable communication equipments,

4. Monitor, Portable camera, Telecommunication, digital products

How to choose the right chip inductor for SMT chip processing?

1. The total width of the chip inductor should be lower than the total width of the inductor to avoid excessive soldering materials from causing excessive tensile stress to change the inductor value when the water is cooled.

2. The precision of the chip inductors available on the sales market is mostly ±10%. If the precision is higher than ±5%, you must order early.

3. Some chip inductors can be welded by reflow oven and wave soldering, but there are also some chip inductors that cannot be welded by wave soldering.

4. When overhauling, it is not possible to replace the inductor with a chip inductor only by the amount of inductor. In order to ensure the operating characteristics, it is also necessary to understand the operating frequency range of the chip inductors.

5. The appearance design and specification basis of the chip inductors are similar, and the appearance design does not have a significant mark. When hand-soldering or hand-made patches, you must be very careful and don’t make mistakes or pick up the wrong parts.

6. At this stage, there are three common chip inductors: the first type, high-frequency inductors for microwave heating. Applicable for frequency range applications around 1GHz. The second type is high-frequency chip inductors. It is suitable for series resonance control circuit and frequency selective power supply circuit. The third type is practical inductors. Generally applicable to power circuits of tens of megahertz.

7. Different products use different diameters of magnetic coils. Even if the same amount of inductor is used, the resistance measurement displayed is not the same. In the high-frequency control loop, resistance measurement is very harmful to the Q value, so pay attention to it when designing the scheme.

8. It is allowed to be an index value of the chip inductance according to the larger amount of current. When the power supply circuit must be responsible for the large amount of current, this index value of the capacitor must be taken into consideration.

9. When power inductors are used in DC/DC converters, the size of their inductors immediately endangers the working attitude of the power circuit. According to the actual situation, the method of adjusting the magnetic coil can usually be used to change the inductors to achieve practical results.

10. Wire-wound inductors are common in communication equipment operating in the frequency range of 150~900MHz. In the frequency power circuit around 1GHz, microwave heating high-frequency inductors must be used. When the customer applies the smt patch type, of course, it is also stipulated in various aspects. Only the processing party can confirm that it is truly integrated into the sales market after considering the full-level regulations of the customer.

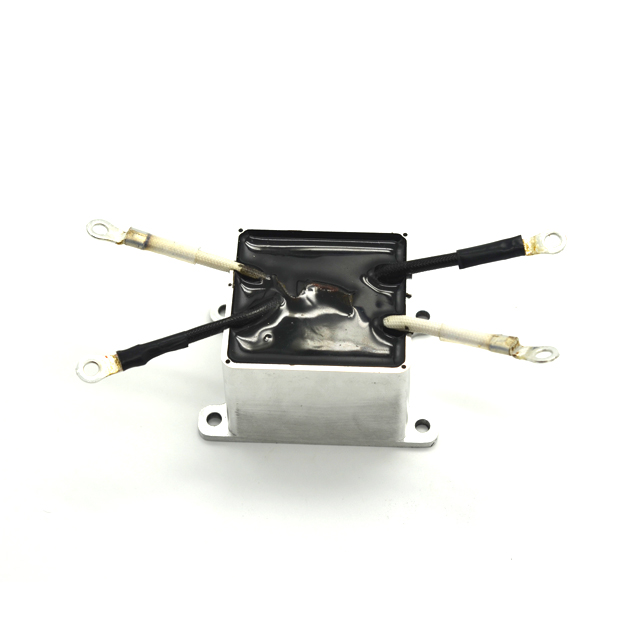

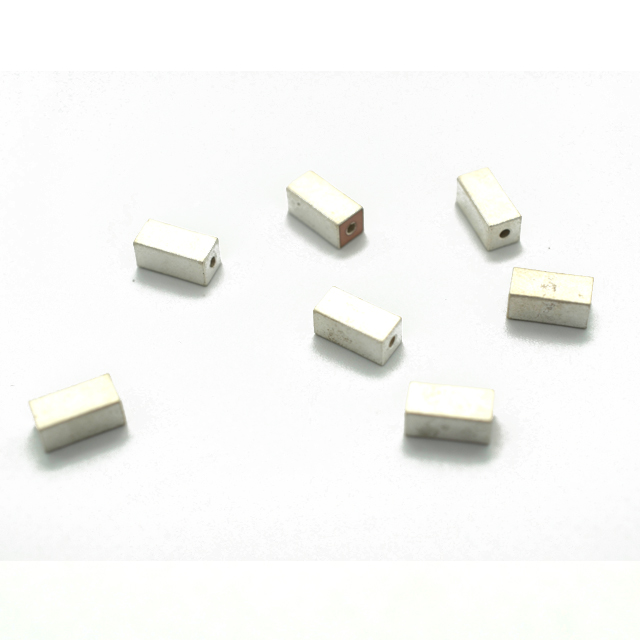

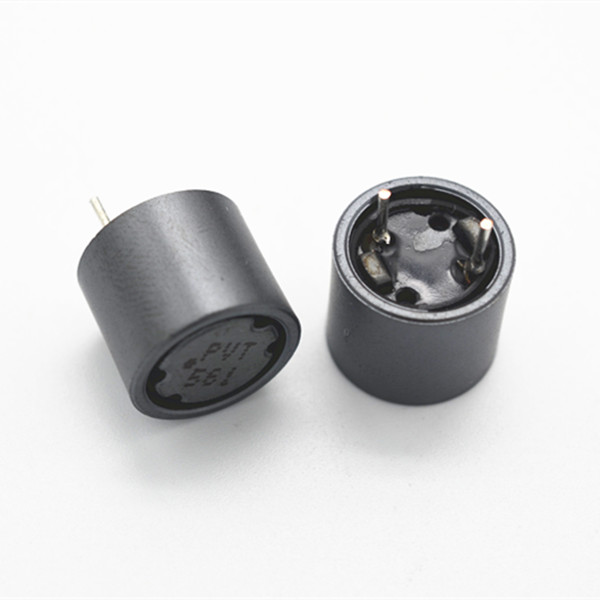

Product detail pictures:

Related Product Guide:

What’s the role common mode choke play in daily?

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Massive Selection for Common-Mode Inductor - SMT power inductor – Mingda , The product will supply to all over the world, such as: Iraq, Qatar, Mecca, With the first-class solutions, excellent service, fast delivery and the best price, we've won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.