Inductor air coil

Air coil models an air core coil inductor with centered axial leads. Coil and lead dimensions are configurable.

We have exported this kind of SMD inductor coil mainly to USA, UK, Germany, Korea and Canada.

Advantages:

1.Customized according to your unique request

2.Very high precision

3. All products 100% tested

4. Build to confirm ROHS compliant

5.Short lead time and quick sample

6. Pick and place process possible

7. Good solderability (tinned connector pins)

8.Tape&Reel packaging

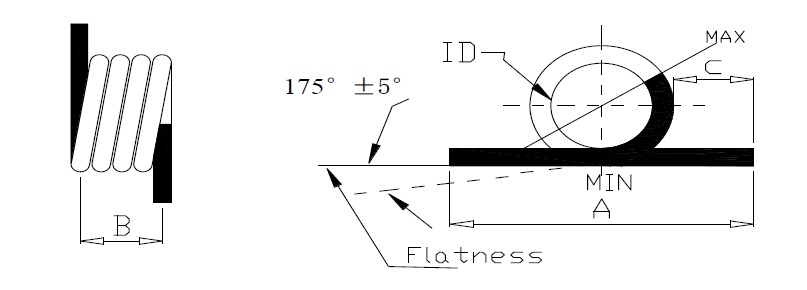

Size and dimensions:

| ID+0.1/-0 .05 | TURNS |

A(REF) |

B(REF) |

C±0.2 |

|

3 |

11 |

6.5 |

3.8 |

1. 5 |

Parameters

| Name | Description |

| ID | Subcircuit ID |

| NET | Subcircuit name |

| *M | Multiplicity factor – not used for this model |

| NTurns | Number of turns |

| WireDia | Diameter of the wire |

| CoilDia | Coil inner diameter |

| Pitch | Distance between turns, measured from wire center-to-center |

| LeadLen | Length of lead |

| LeadOff | Offset distance between coil body and beginning of lead |

| LeadType | Type of lead contact: 0=round post, 1=bottom flat tab, 2=lofted flat tab |

| TabLenRatio | Ratio of tab length to total lead length for LeadType=1 or 2. 0<TabLenRatio<1 |

| Rho | Bulk resistivity of conductor metal normalized to gold |

Application:

1. Satellite communication systems

2. Test equipment and microwave equipment

3.Television circuits.

4.Transmitters and band pass filters.

Do you need an air coil?

What are the advantages of an air core coil?

Its inductance is unaffected by the current it carries. This contrasts with the situation with coils using ferromagnetic cores whose inductance tends to reach a peak at moderate field strengths before dropping towards zero as saturation approaches. Sometimes non-linearity in the magnetization curve can be tolerated; for example in switching converters. In circuits such as audio cross over networks in hi-fi speaker systems you must avoid distortion; then you need an air coil. Most radio transmitters rely on air coils to prevent the production of harmonics.

Air coils are also free of the ‘iron losses’ which affect ferromagnetic cores. As frequency is increased this advantage becomes progressively more important. You obtain better Q-factor, greater efficiency, greater power handling, and less distortion.

Lastly, air coils can be designed to perform at frequencies as high as 1 Ghz. Most ferromagnetic cores tend to be rather lossy above 100 MHz.

And the ‘downside’?

Without a high permeability core you must have more and/or larger turns to achieve a given inductance value. More turns means larger coils, lower self-resonance and higher copper loss. At higher frequencies you generally don’t need high inductance, so this is then less of a problem.

Greater stray field radiation and pickup. With the closed magnetic paths used in cored inductors radiation is much less serious. As the diameter increases towards a wavelength (lambda = c / f), loss due to electromagnetic radiation will become significant. Balanis has the gory details. You may be able to reduce this problem by enclosing the coil in a screen, or by mounting it at right angles to other coils it may be coupling with.

You may be using an air cored coil not because you require a circuit element with a specific inductance per se but because your coil is used as a proximity sensor, loop antenna, induction heater, Tesla coil, electromagnet, magnetometer head or deflection yoke etc. Then an external field may be what you want.