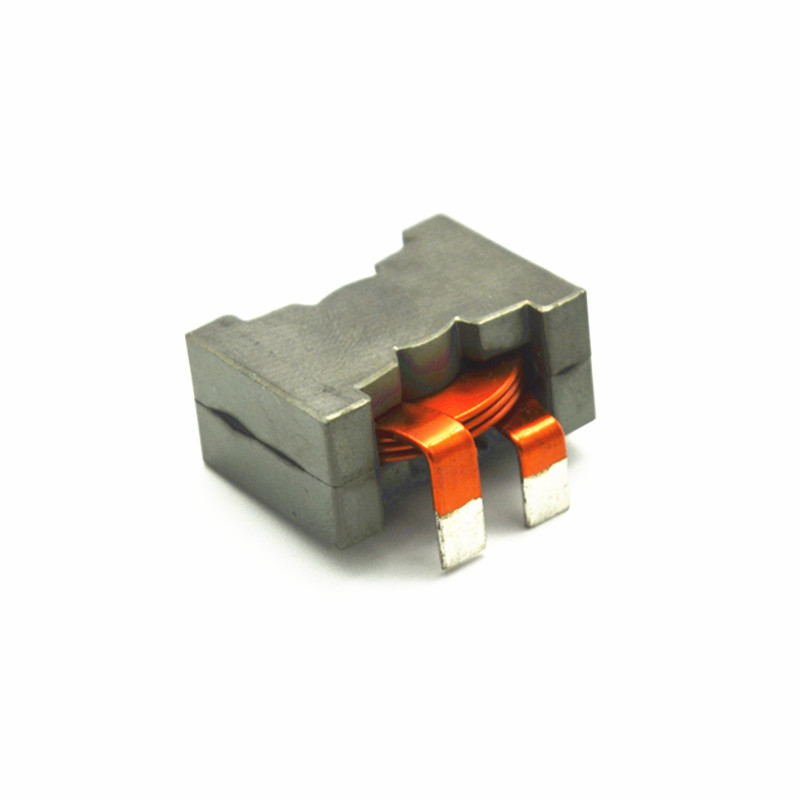

High Current Wirewound Customize Good Quality Factory Product

1.Use flat wire material AIWJ wire, temperature resistance class is 220℃

2. Helical winding, semi-quasi-planar structure with low skin effect loss.

3. Compared with the round wire, the flat wire has the characteristics of light weight, low resistance, high efficiency and low noise under the same volume.

4. It is made of high-quality low-loss mixed materials, iron powder core and ferrite materials. Under the same size, it can withstand higher currents and is suitable for a wider frequency of 1KHZ~5MHZ. The product has high working efficiency and better Q value. stable.

5. The product structure is simple, the performance is stable, and the temperature difference inside the coil is small, so the heat dissipation performance and the magnetic field efficiency can obtain better performance.

6. Inductances with different inductances from 0.1uH to 200uH can be manufactured, which can withstand direct current from 10A to 200A, and the instantaneous current can reach 250A or even higher.

7. The product can support multiple installation methods such as patch and plug-in.

8. Different types of inductors can be designed according to customer requirements. Product application: Suitable for computer, power supply, military industry, communications, electric power, industrial power supply, video recorder, digital camera, audio and video equipment, automotive DC/DC converter/electric hybrid system, heavy industrial machinery and various industrial products.according to customer requirements. Our customers provide perfect products and services.

At present, in low-voltage and high-current DC-DC converters, a brand-new, low-profile, high-power-density output inductor is widely used. This inductor uses a high-frequency low-loss ferrite core, and is resistant to high current and extremely low A combination of lossy planar windings.

The demand for DC-DC modules that meet the power supply requirements of new processors will require 25A, 50A.100A output inductors. This requires DCR, ACR and leakage inductance of the output inductor to be very small. Therefore, the use of spiral technology is the best solution to meet the above requirements. Mingda has invested a lot of money and energy in the design and production of spiral coils, and has accumulated rich design and production experience. It can improve the ability of spiral coils of various specifications, and can also design and open molds

Advantages:

1. Magnetic shielding structure, excellent resistance to electro magnetic interference.

Assemblage design, sturdy structure.

2. Build to RoHS compliance and lead free

3.Small volume, high current, low magnetic loss, low ESR, small parasitic capacitance.

4.Temperature rise current and saturation current is less influenced by environment.

5. For the packaging, both bulk packaging or tape&reel packaging is OK.

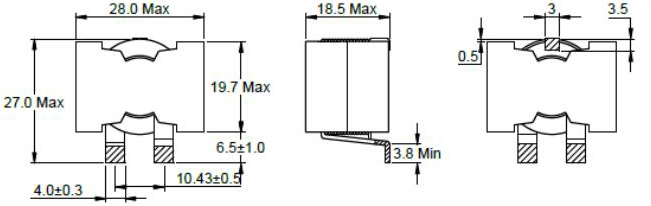

Size and dimensions:

Applications:

1. used for audio products, automotive electronics

2. DC/DC converters, High Q filters, temperature stabilized filters, telecom filters, Output chokes, Load coils and EMI filters