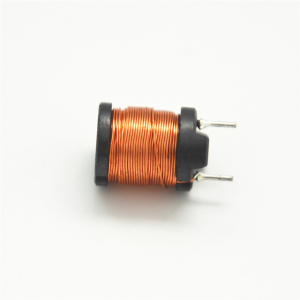

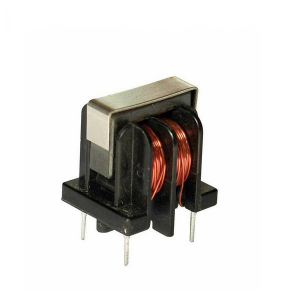

Flat Wire Air Coil

It’s that each turn is wound into a spiral shape by multiple parallel deflection wires, divided into single helix, double helix and four helix winding methods. The wires need to be transposed. The spiral coil is wound into a spiral like the cylindrical coil. The difference is that the former has more wires per turn, and the wires are stacked, and each turn is not tight to each other like a cylindrical coil. Lily, but there is a gap in the middle. Compared with continuous coils, helical coils have fewer turns, larger cross-sections, and larger supporting end surfaces, and have good stability in the event of an axial short circuit. Therefore, spiral coils are suitable for high-current low-voltage coils, or for large power transformers where continuous coils are not suitable.

Through hole mount with pre-tinned leads that can be directly soldered to PCB

For custom requirement, please specify the specs (size, inductance, current) and we built to meet the specs.

Advantages

1.No core losses

2.Extremely high Q-Factor

3. Ultra low RDC, High current capability

4.Customized according to your unique request

5. Precision wound coil and 100% all tested to ensure the quality.

6. Build to confirm ROHS compliant

7.Short lead time and quick sample

8.Samples could be provided for your testing

Size and dimensions

Application

1. RF power amplifiers, RF-Voltage regulators

2.High current RF filters/chokes

3.Power supplies, Magnetically-sensitive applications