-

Wholesale Price China China High Frequency Customized Power Line Filter Common Mode Choke Line Filter Coils Uu Type Inductor for Power Usage PCB Assemblies

With below information, we could help to customized the product:

1. Current and inductance request

2. Working frequency and size request

UU10.5, UU9.8, UU16 is available for your choice.

-

Wholesale Price China China High Frequency Customized Power Line Filter Common Mode Choke Line Filter Coils Uu Type Inductor for Power Usage PCB Assemblies

With below information, we could help to customized the product:

1. Current and inductance request

2. Working frequency and size request

UU10.5, UU9.8, UU16 is available for your choice.

-

Best Price for China 4.7uh 47uh 470uh 6.8uh 68uh 680uh 22 Uh 330uh 100uh Cdrh74 Cdrh104 Cdrh127 SMD Shielded Ferrite Core Power Inductor

This type SMT power inductor is widely used for LED, Digital products, LED drive.

With open unshielded design, it has Low tolerances at high inductance values, The size is small.

-

factory low price China RM8 Type Mn-Zn Ferrite Core SMD Power Choke Filter Inductor

We could provide different type and size of SMD common mode inductors. In situations where noise occurs around a signal, Ming Da’s broad range of common mode chokes suppresses interference cleanly and efficiently without compromising signal integrity. Used in moderate to severe conditions like telecommunications systems, industrial equipment and automotive power supply, our extensive portfolio of products is designed to filter noise and optimize application performance and power supply. Our unique materials withstand high temperature and power situations and will keep your systems running consistently and at top speed.

-

Hot New Products China Toroidal Choke Coil Filter Inductor with Ferrite Rod Core UL RoHS Certificate

Ferrites are dense, homogenous ceramic structures made by mixing iron oxide with oxides or carbonates of one or more metals such as zinc, manganese, nickel or magnesium. They are pressed, then fired in a kiln at 1,000 – 1,500°C and machined as needed to meet various operational requirements. Ferrite parts can be easily and economically molded into many different geometries. A diverse set of materials, providing a range of desired electrical and mechanical properties, are available from Magnetics.

-

Manufacturer of China Wire Wound Power Inductor for TV with RoHS

Core Material: Iron Power Core

With Helical Wound Surface Mount inductor, It is Capable of handling very high DC bias current with low inductance roll off.

Induction/Size/Wire diameter/Electric Current :Normally our customer specify the specs (size, inductance, current) and we built to meet the specs.

-

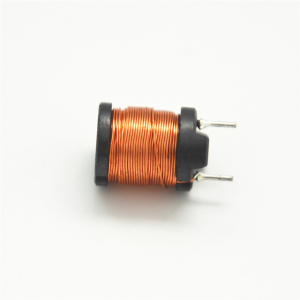

Factory Supply China High Frequency Inductive Coil Copper Wire Wireless Coil for Toy

The I-shaped inductor is an electromagnetic induction element composed of an I-shaped magnetic core frame and enameled copper wire. It is a component that can convert electrical signals into magnetic signals. The I-shaped inductor itself is an inductor. The skeleton of the I-shaped inductor is supported by the winding of the copper core coil. I-shaped inductance is one of the attributes of electronic circuits or devices.

-

High definition China Enamelled Flat Copper Wire Winding Coil Air Core Inductor Coil

PFC inductor, also called toroidal inductor, Capable of handling very high DC bias current with minimal inductance roll off.

“Power Factor Correction” The power factor is the ratio of the effective power divided by the total power consumption (apparent power).

-

Factory Customized China SMD Unshielded Power Inductors with ISO9001 Approved

This type SMT power inductor is widely used for LED, Digital products, LED drive.

With open unshielded design, it has Low tolerances at high inductance values, The size is small.

-

Factory supplied China Common Mode Choke Coils, Applicable for EMI in LED Driver

Power line CM chokes eliminate EMI with high isolation voltages to meet FCC, CISPER, and other EMI / RFI standards.

Combination line filter chokes filter common mode (CM) and differential mode (DM) noise in a single component.

-

Top Grade China Power Choke Filter SMD Ferrite Magnetic Core Ring Coil Inductor

The shielded patch power inductor is a kind of Gree magnetic field interference. The use of a good magnetic cover to achieve electromagnetic shielding can not only prevent the interference of the peripheral electromagnetic field, but also a shielding measure that does not interfere with the operation of other peripheral components.

-

Top Grade China Power Choke Filter SMD Ferrite Magnetic Core Ring Coil Inductor

The shielded patch power inductor is a kind of Gree magnetic field interference. The use of a good magnetic cover to achieve electromagnetic shielding can not only prevent the interference of the peripheral electromagnetic field, but also a shielding measure that does not interfere with the operation of other peripheral components.